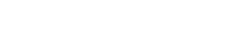

Nike’s 3D printed footwear surges through the popularity among the crazy US youths. Founded in 1964, Oregon based Nike, Inc. has made an impression among its users across the world with the products. As most of us already know the company’s intension to create a global product in the likes of 3D printed shoes, the brand new Vapor Carbon 2014 Elite Cleat has already been introduced in this year’s Super Bowl.

The formation of this elite cleat took almost two decades of research and insight to bring out the best performance. The game of football is mixed with speed, power and acceleration -- Vapor Carbon 2014 Elite Cleat considered to be best fit in the game. This cleat featured a 3D printed nylon based plate that Nike called the V-Plate.

But this seems to be a beginning only. The company is using 3D printing in a big way to bring a revolution in the shoe designing and prototyping, particularly cleat. There are some more to come. The new Nike Vapor Laser Talon concept cleat, which has been made, uses 3D printing technology.

Nike, Inc. appears to be extremely serious in promoting this footwear made of using 3D printing techniques. The signal indicates that the majority of the shoes would be 3D printed in days to come.

The advancement of technology will speed up the printing process and make it more accurate by the time. It will be an economically viable path to reach, especially if they are able to lock up key patents within the industry, like they have begun doing.

The brains behind Vapor Carbon 2014 Elite Cleat are director of innovation Shane Kohatsu and designer Ken Link commend their product, but the endorsement came from Olympic legend sprinter Michel Johnson. Johnson, owner of MJP training centre, a Nike athlete lauded the 3D printed product. He was joined by Lance Walker, director of performance, MJP training centre and NFL start athlete Marqise Goodwin.

The method that have used here is designing a three-dimensional pattern for printing, positioning at least a portion of the article on a tray in a three-dimensional printing system, the portion being positioned substantially flat on the tray, printing a three-dimensional material directly onto the article using the designed pattern, curing the printed material, and removing the article from the three-dimensional printing system.

There are many more exciting apparel products to come in future on behalf of the company.

- Cover Story

-

SketchUp Can Help You Win Interior..

SketchUp Can Help You Win Interior.. -

Best Laptops for SketchUp

Best Laptops for SketchUp -

How to Resize Textures and Materials..

How to Resize Textures and Materials.. -

Discovering SketchUp 2020

Discovering SketchUp 2020 -

Line Rendering with SketchUp and VRay

Line Rendering with SketchUp and VRay -

Pushing The Boundary with architectural

Pushing The Boundary with architectural -

Trimble Visiting Professionals Program

Trimble Visiting Professionals Program -

Diagonal Tile Planning in SketchUp

Diagonal Tile Planning in SketchUp -

Highlights of some amazing 3D Printed

Highlights of some amazing 3D Printed -

Review of a new SketchUp Guide

Review of a new SketchUp Guide

- Sketchup Resources

-

SKP for iphone/ipad

SKP for iphone/ipad -

SKP for terrain modeling

SKP for terrain modeling -

Pool Water In Vray Sketchup

Pool Water In Vray Sketchup -

Rendering Optimization In Vray Sketchup

Rendering Optimization In Vray Sketchup -

Background Modification In sketchup

Background Modification In sketchup -

Grass Making with sketchup fur plugin

Grass Making with sketchup fur plugin -

Landscape designing in Sketchup

Landscape designing in Sketchup -

Apply styles with sketchup

Apply styles with sketchup -

Bedroom Making with sketchup

Bedroom Making with sketchup -

Review of Rendering Software

Review of Rendering Software -

Enhancing rendering for 3d modeling

Enhancing rendering for 3d modeling -

The combination of sketchup

The combination of sketchup -

Exterior Night Scene rendering with vray

Exterior Night Scene rendering with vray