Author : Debarati Nath

Bring Ur Idea to Life in 3 Dimension:3D Printing and SketchUp

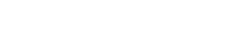

Building a house of our own is the precious dream of everyone’s life. SketchUp helps you to see the house virtually on the monitor of your computer. But there is something more exciting than only to see the house virtually. And 3D Printing makes possible to touch, feel and see your dream house in reality. 3D Printing is the way to hold the 3D model of your house in hand. And SketchUp helps you to achieve the perfection of your dream comes reality.

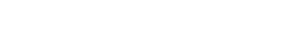

3D Printing is a well searched word for the architectural, industrial design, engineering, construction, automotive, aerospace, medical, jewelry, footwear and in many more sectors. 3D Printing is a process in which three dimensional objects can be created from the digital file of the 3D designing software like SketchUp. With the help of SketchUp and 3D Printing, you can have a miniature 3D model of the thing you design in SketchUp. 3D Printing has now become immensely popular in designing and architectural sectors. With the help of the 3D printing the architects can give their clients an opportunity to touch their dream. There are many companies who provide 3D Printing services for SketchUp like i.materialise, Shapeways, CADSpan, Sweet Onion and many more.

There are many methods of 3D printings are available in the market. Their main differences are found in the way layers are built to create parts. Some methods use melting or softening material to produce the layers, e.g. selective laser sintering (SLS) and fused deposition modeling (FDM), while others lay liquid materials that are cured with different technologies, i.e. stereolithography (SLA). In the case of laminated object manufacturing (LOM), thin layers are cut to shape and joined together (i.e. paper, polymer, metal). Each method has its advantages and drawbacks, and consequently some companies offer a choice between powder and polymer as the material from which the object emerges.[3] Generally, the main considerations are speed, cost of the printed prototype, cost of the 3D printer, choice and cost of materials and colour capabilities.

Fused Deposition Modeling or FDM is a technology in which a nozzle is used to deposit molten polymer like ABS, PC or PPSU on a support structure in layer by layer. Another well known method is the selective fusing of print media in a granular bed. In this process the unfused media give the support to the overhangs and thin walls in the part being produced. In this way it reduces the requirements of the auxiliary temporary supports for the workpiece. Generally a help of laser is taken to form the media and shape the solid part. Another similar kind of 3D Printing named Electron Beam Melting is used for metal parts like titanium alloy. For food grade art objects the CandyFab printing system is being used. In Inkjet printing system the printer itself creates the model layer by layer by spreading the plaster or resins powder. There is another method called Photopolymerization in which the liquid polymer is exposed to light from a DPL projector under safelight conditions.

Though 3D Printing is a great tool for design visualization, prototyping/CAD, metal casting, architecture, education, geospatial, healthcare and entertainment/retail industries but it is god send gift for the architectural industry. The five benefits of 3D Printing are:

-

Increase innovation

-

Improve communication

-

Speed time to construction

-

Reduce costs

-

Win Business

Three dimensional printing or 3D Printing is an outstanding way to visualize and communicate your architectural ideas and concepts with the clients. There’s simply no substitute for the tactile and visual feedback a physical model can provide – and with Dimension, you can create both simple and complex models in real space and proportionately scaled.

A Dimension Printer could create the same model in just hours. Dimension 3D printers also allow you to experiment with new concepts and numerous design iterations – without extensive time or building expense. It is always a good experience to see your dream in a miniature form before executing.

The already wide-range applicability of 3D printing is readily apparent, albeit, currently limited to prototypes and models. However, many companies are already investing heavily into the next phase of 3D printing, referred to as direct digital manufacturing, D.D.M., which will facilitate increased printing quality and capability, such as manufactured goods. A few examples of these next-phase capabilities include printing spare parts for all sorts of appliances and vehicles instead of ordering them from manufacturers and having to wait for delivery and pay for the cost of shipping — a godsend for anyone who owns a Volvo. 3D concrete printing would even allow for on-site printing of large-scale building materials for any specification, currently being worked on by Loughborough University in England; it could even print food.

But it’s not all about the big industry uses; 3D printing already exists today for cultural, personal and individual use. Anyone with around $1,200 to $2,000 can buy their own 3D printer from a number of different websites like makerbot.com or bitsfrombytes.com. Of course the cartridges of materials are extra costs, but in my opinion, having the ability to print any shape or object you can think of is well worth it. Although this process is in the very early stages of development and many people have yet to hear about it or come to an understanding of it, the fact that it is already a reality is remarkable; the fact that it’s just getting started is extraordinary. Even as I write this I can’t wrap my head around the implications of 3D printing in our already-advancing society; the possibilities seem fascinatingly endless and remedies to issues of varying significance become more and more apparent.

There are a few companies who can deliver the 3D printing when your place your order by uploading the SketchUp model on their website. Companies like i.materialise, Shapeways, Sweet Onions and CADspan have made the 3D printing is an easy thing. Generally the 3D printing of the SketchUp model consists various types of file conversion, scale conversion and quite a bit of checking for many things. But now many plug ins are available to make the SketchUp to object printing process is the easiest one. The plug ins help the users to create a scale model of your SketchUp design which is ready to upload it for 3D printing.

- Cover Story

-

SketchUp Can Help You Win Interior..

SketchUp Can Help You Win Interior.. -

Best Laptops for SketchUp

Best Laptops for SketchUp -

How to Resize Textures and Materials..

How to Resize Textures and Materials.. -

Discovering SketchUp 2020

Discovering SketchUp 2020 -

Line Rendering with SketchUp and VRay

Line Rendering with SketchUp and VRay -

Pushing The Boundary with architectural

Pushing The Boundary with architectural -

Trimble Visiting Professionals Program

Trimble Visiting Professionals Program -

Diagonal Tile Planning in SketchUp

Diagonal Tile Planning in SketchUp -

Highlights of some amazing 3D Printed

Highlights of some amazing 3D Printed -

Review of a new SketchUp Guide

Review of a new SketchUp Guide

- Sketchup Resources

-

SKP for iphone/ipad

SKP for iphone/ipad -

SKP for terrain modeling

SKP for terrain modeling -

Pool Water In Vray Sketchup

Pool Water In Vray Sketchup -

Rendering Optimization In Vray Sketchup

Rendering Optimization In Vray Sketchup -

Background Modification In sketchup

Background Modification In sketchup -

Grass Making with sketchup fur plugin

Grass Making with sketchup fur plugin -

Landscape designing in Sketchup

Landscape designing in Sketchup -

Apply styles with sketchup

Apply styles with sketchup -

Bedroom Making with sketchup

Bedroom Making with sketchup -

Review of Rendering Software

Review of Rendering Software -

Enhancing rendering for 3d modeling

Enhancing rendering for 3d modeling -

The combination of sketchup

The combination of sketchup -

Exterior Night Scene rendering with vray

Exterior Night Scene rendering with vray